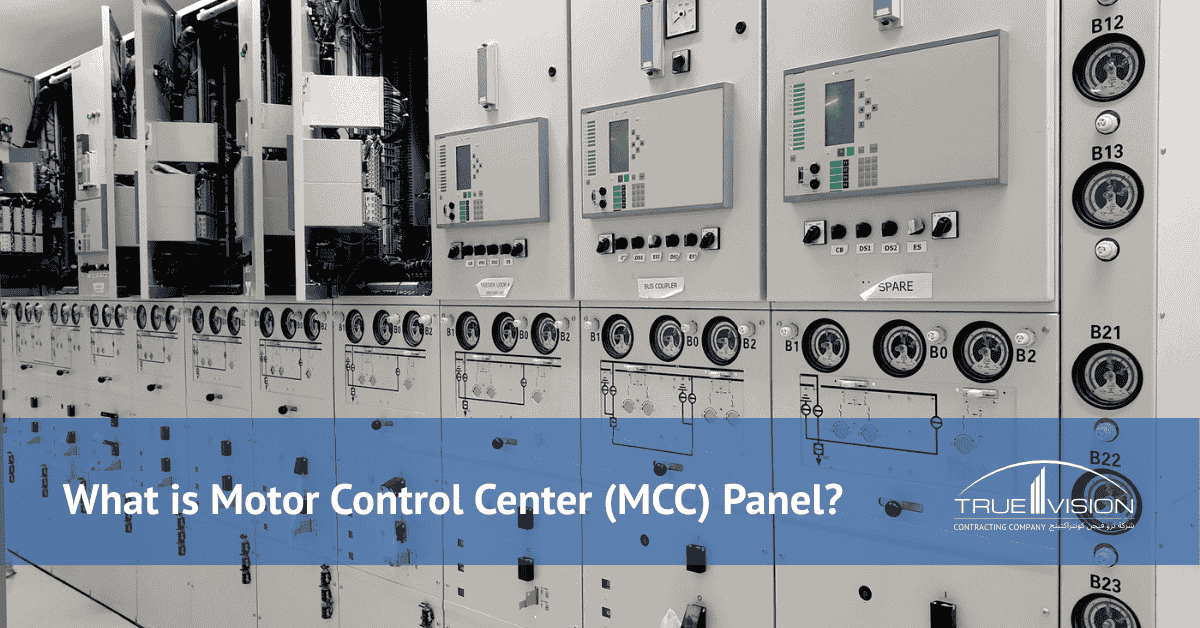

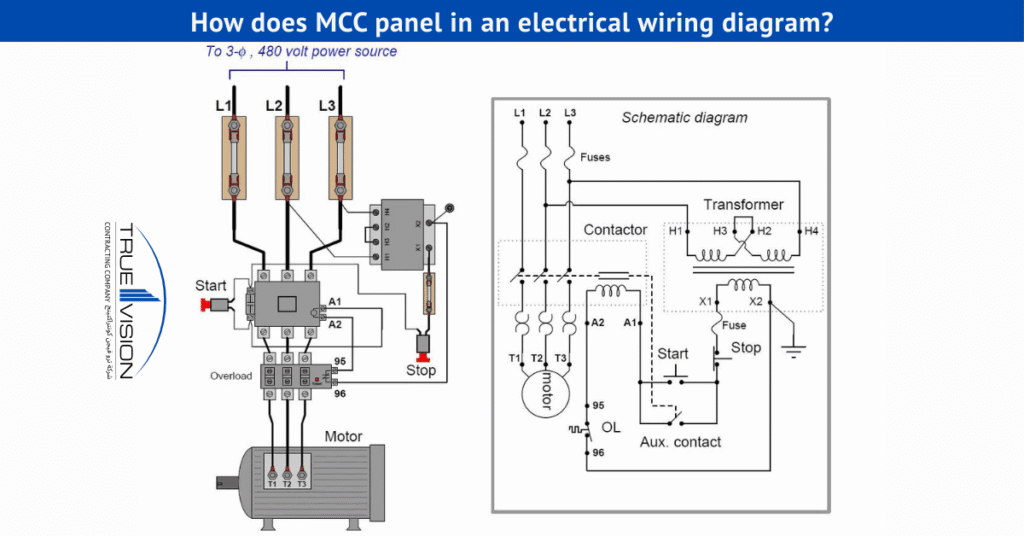

MCC Panel: Work, Specs, Type, Components, Manufacturers

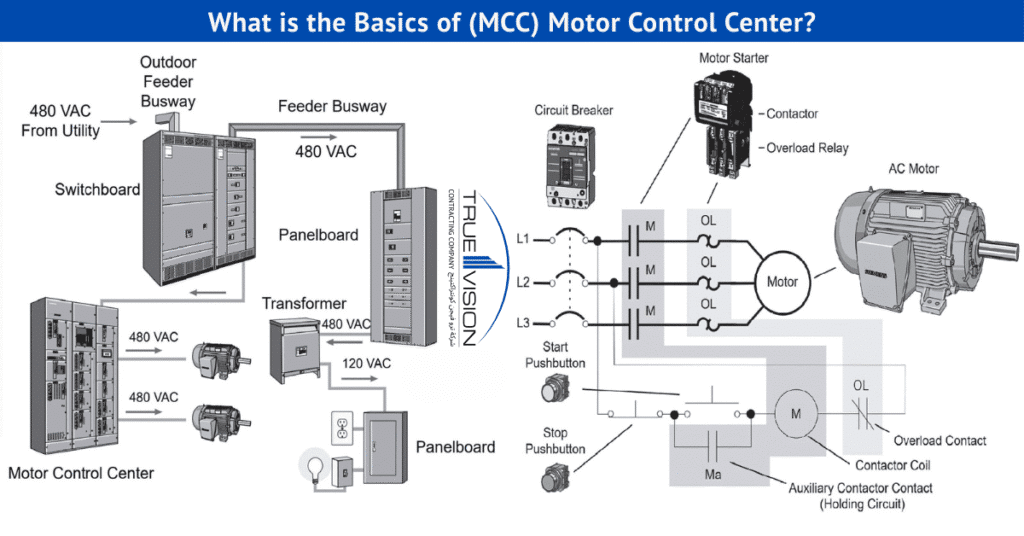

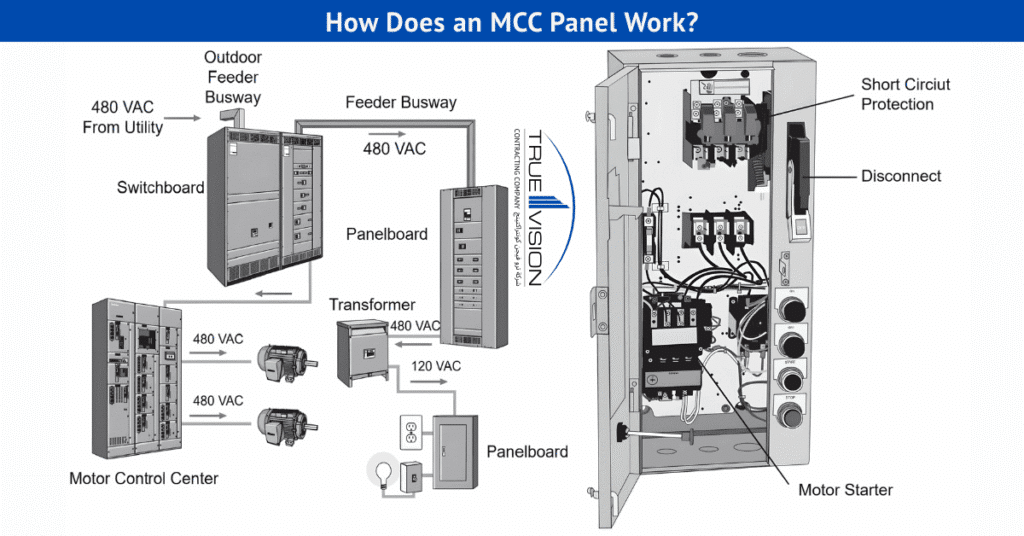

Motor Control Center (MCC panel) is essential for industries that run multiple motors at once. These systems centralize control, boost safety, and improve efficiency in facilities such as manufacturing plants, power stations, and commercial complexes. By understanding MCC panels, businesses can optimize energy use, cut costs, and ensure reliable motor performance.