What is PLC Programming? Examples, Software, Languages, Work

PLC programming is the backbone of industrial automation. It turns sensors, motors, and machines into coordinated systems that work safely, repeatably, and fast.

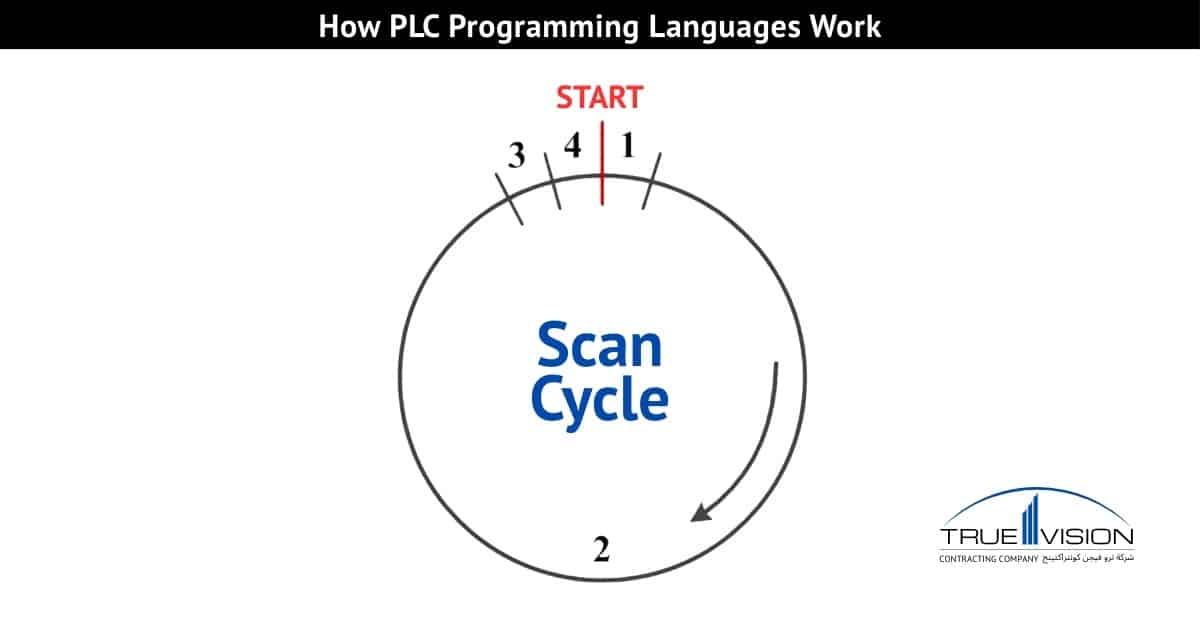

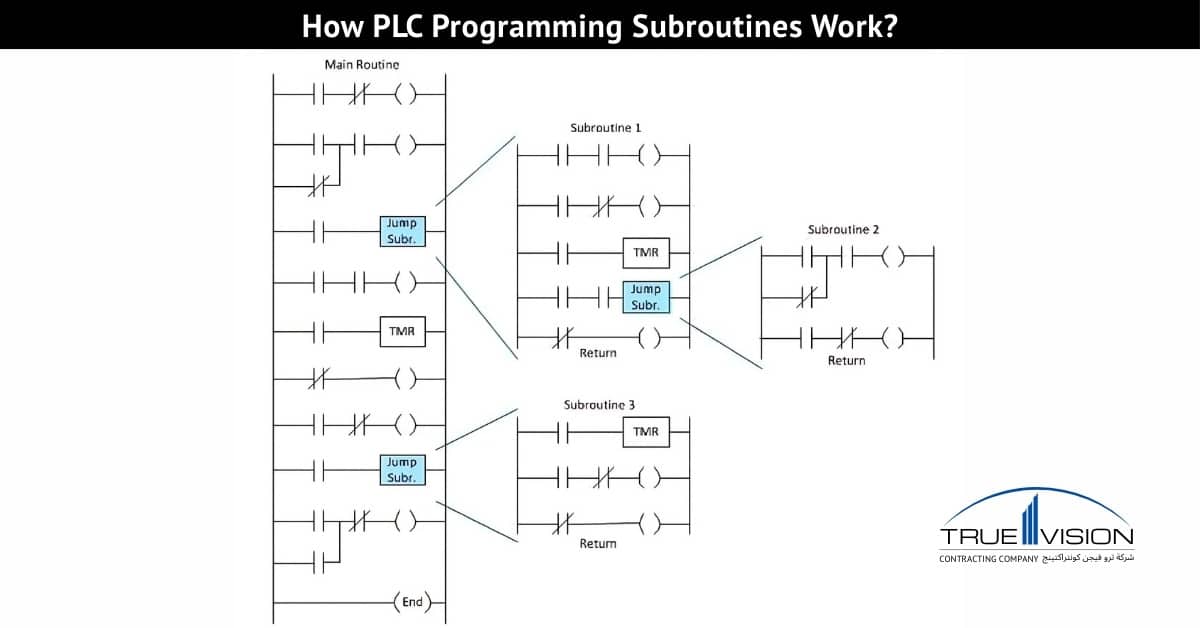

Read further to learn what PLC programming is, how programs are organized, how to get started, practical examples in each IEC 61131-3 language, and how major vendor tools (B&R, ABB, Schneider/Modicon, Fatek) fit into your workflow. You’ll also learn how tasks, scan cycles, and subroutines work so you can write clean, reliable code from day one.