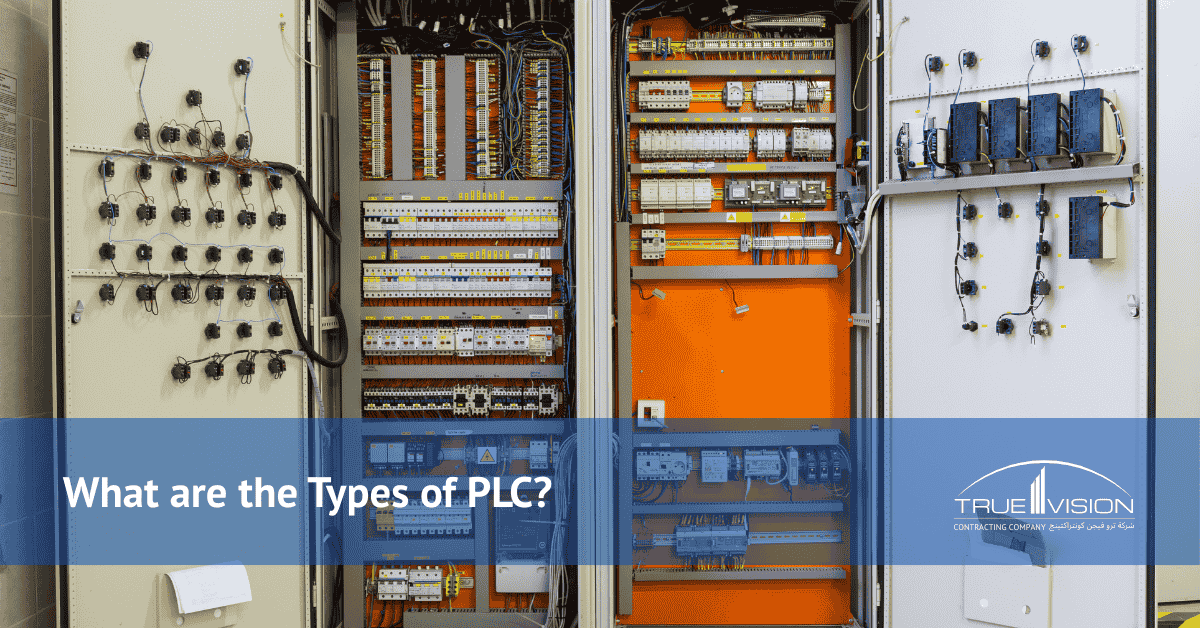

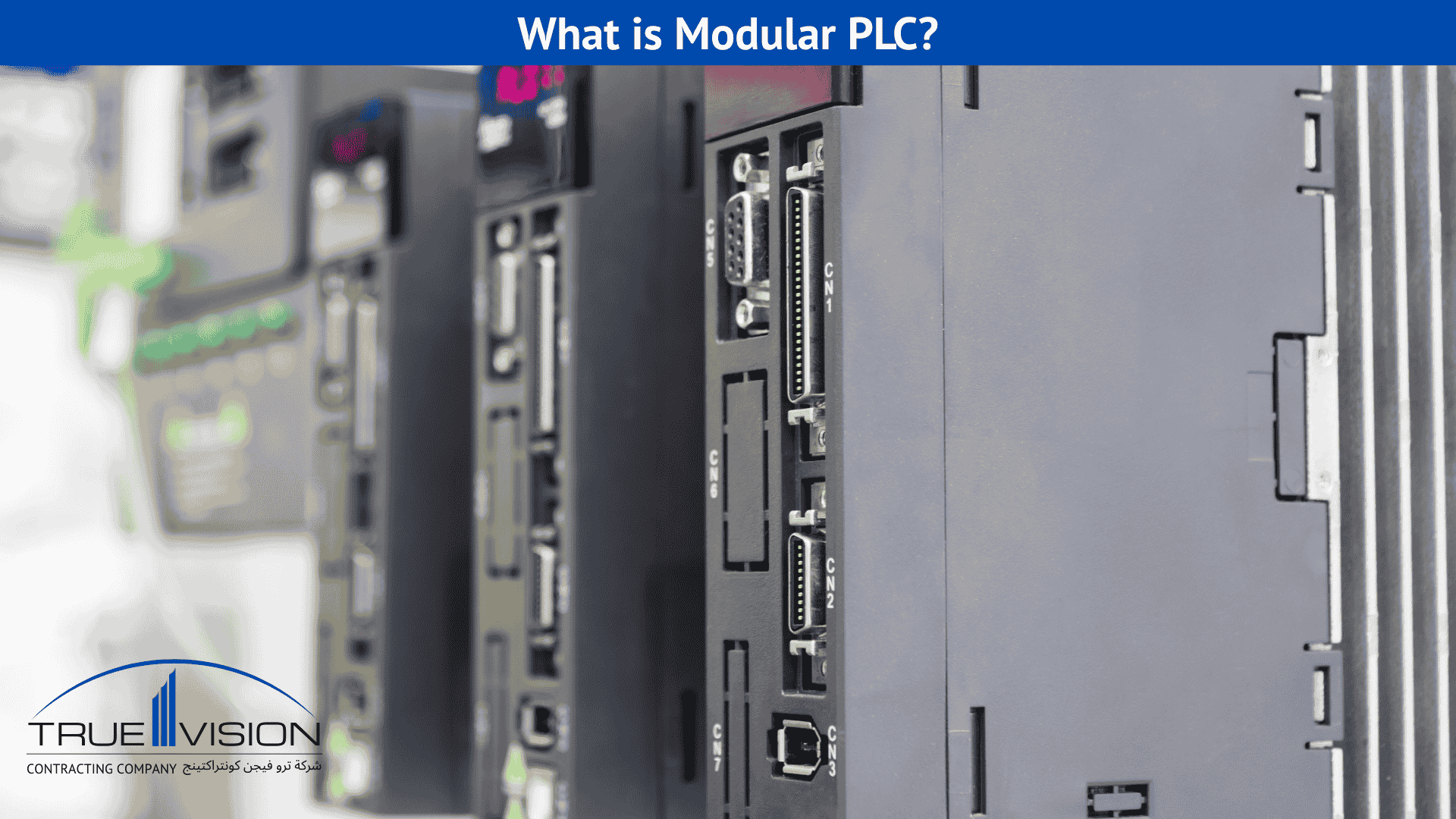

Type of PLC: Programming, Output, Size, Design, Brands

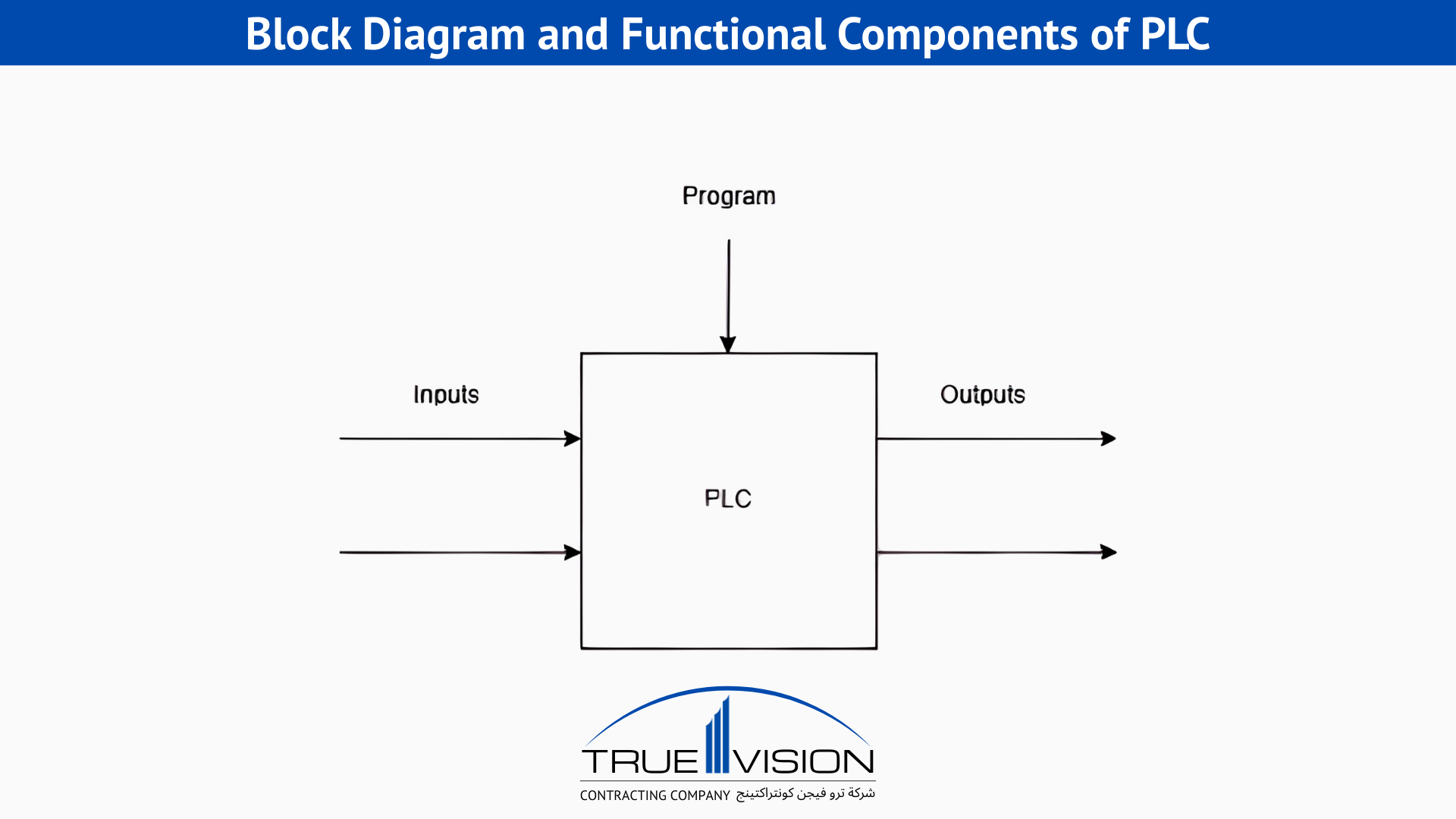

Modern manufacturing relies heavily on automation, and the choice of controller can significantly impact efficiency. From programming flexibility to output type, size, design, and brand ecosystem, each factor plays a crucial role in performance. Understanding these elements is the first step in determining what a PLC is and why it matters in the industrial world.